Introduction

If you are associated with the world of printing technology, you must have heard the term UV 3d printer. The scenario of modern product branding has shifted towards the world of digital printing. However, the rules for short-run businesses and some independent creators in the world of printing have now changed with the emergence of the UV 3d printer.

With the use of this technology, high-detailing tactile prints are now possible without using any kind of expensive plate or screen. Due to its features this particular printing technology is considered the backbone of all kinds of short-run production.

But what is short-run production that we are talking about?

By short-run production, it means manufacturing of products in small quantities. It often ranges from a single unit to almost a few hundred at a time.

What Is the Role of the UV 3d printer in The World of Manufacturing

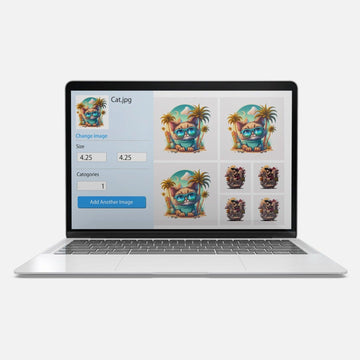

UV 3d printers including SLA and DLP technology support small-run production. A UV 3d printer uses the ultraviolet light or the UV light to cure the ink instantly when it is applied to a substrate or a film that acts as its carrier. In the world of business, branding and labeling is very common. These processes involved together help in creating unbeatable UV DTF transfers.

DTF stands for Direct-to-Film transferring procedure. The UV 3d printer gives a three dimensional effect to all the prints that come through it.

Knowledge Tip: This 3D feature gives the products a premium feel that was previously possible through expensive molding or engraving.

Primary Benefit: The primary advantage with an UV 3d printer is the removal of setup barriers. Just because the entire process is completely digital, anyone who wants immediate yet different printouts can print around five separate designs in a day. You will also not need to stop in the middle for changing the screens or mixing the large batches of ink. It is due to this kind of flexibility that the UV 3D printer is an essential tool for companies that are planning to quickly respond to the feedback of the buyers or respond towards the seasonal trends.

How to Produce High-Impact 3D UV stickers for Branding Purposes

Production of 3D UV stickers is one of the popular invention of this technology. These stickers are not any average labels of paper. They are constructed after using multiple layers of specialized UV ink. The finishes of these 3D UV stickers come with clear gloss or matte varnish that make these products stand out from the surface. The result is just like a tactile emblem which people can feel when they run their fingers over it.

How to Improve the Look of Product Packaging

For a small business, making use of 3D UV stickers is an effective way to improve the look of product packaging without any huge investment. These stickers are mostly used in the custom-printed boxes or bottles. It is the raised texture of the stickers that points out a level of quality to every detail that is mentioned on it to promote a brand and stand out on the crowded shelf.

You can apply these stickers to almost any hard surface, and they give a feel as if these stickers are directly printed onto those items. This is particularly useful for short-run business products and items. For example, artisanal candles, boutique cosmetic jars, or on limited edition crafts and also on beer bottles see the usages of 3D stickers.

Here’s The Versatility of Using UV transfer stickers on Various Surfaces

The utility of using this printing method extends far beyond reality. The popularity of UV transfer stickers are known for their incredible durability. Just because the ink is cured instantly with high-intensity UV light, it forms a strong bond. These are resistant to water, sunlight, and physical abrasion.

When businesses look for UV transfer stickers, they seek for a solution that works best on difficult surfaces.

But these transfers work best on:

- Glassware, ceramics including mugs, wine glasses, metal containers and jars

- Electronics like laptops and flasks

- Finished wood products

- Hard plastics

- Acrylics

Why Do Local Businesses Search for UV DTF Printers

With the increasing demand for personalized products, many entrepreneurs are looking for 3D UV stickers by searching with the keyword UV Dtf near me online so that they do not fail to complete the local orders. Distance matters when it is about short-run production because it reduces shipping costs and delivery time. Searching for an UV 3d printer may help small and big businesses support their local economy. It reduces the carbon footprints. For event management planners or the local retailers who need last-minute branded items, having a local partner with an UV 3d printer is a great benefit.

What are the Economic Benefits of Low Minimum Order Quantities

Traditional printing is fueled on the concept of economy of scale. If you buy in bulk, the cheaper the price gets. It is the same scenario with digital UV printing. There is no need for plates therefore there is no plate fee charged from the customer.

A small batch of 3D UV stickers costs about a fraction of what a custom mold would be, yet it offers a similar high-end look. This allows short-run businesses to keep their cash flowing smoothly by only ordering what they need, rather than sitting on unused inventories.

With the expansion of technology we can expect to see even more creative uses of the UV 3d printer. This will further expand the options for those creating UV transfer stickers, with more appealing designs.

Final Thoughts

The UV 3d printer plays a major role in the world of printing businesses as they provide a way to create durable, tactile, and visually stunning branding solutions. Whether you are looking for 3D UV stickers to give your packaging a premium feel or durable UV transfer stickers for industrial applications, the flexibility of this technology is unmatched.

To help short-run businesses associated with the industry, companies like DTF Print are continuously helping to bridge the gap between complex technology and the practical world so that they provide branding solutions with expert results.

Main Aim: Embracing the modern tools, short-run businesses can move away from mass production and towards a more personalized and an efficient future.

Frequently Asked Questions

Q1. What surfaces are best for UV transfer stickers?

Ans: These stickers are designed for hard, non-porous surfaces. They perform exceptionally well on glass, metal, hard plastics, finished wood, and ceramics. They are not recommended for soft fabrics or highly textured, flexible materials.

Q2. How long do 3D UV stickers last?

Ans: Since the ink is cured with ultraviolet light, it is highly resistant to fading and weather. Under normal conditions on a used item like a water bottle or laptop, these stickers can last for years without peeling or losing their color brilliance.

Q3. Is there a minimum order requirement for UV DTF printing?

Ans: One of the main benefits of this technology is the ability to handle very small orders. While many traditional printers require hundreds of units, many providers can accommodate "gang sheets" that fit multiple designs on a single print run, making short-run production very affordable.

Q4. Can I wash items that have UV transfer stickers on them?

Ans: Yes, items branded with these transfers are generally water-resistant and can be hand-washed. However, to maintain the integrity of the 3D varnish effect over a long period, it is usually recommended to avoid high-heat commercial dishwashers.